MRes 2000 [200 mm] Software

MRes Mapper: Take Control with Our Advanced Device Control and Data Acquisition Software

MRes DataViz: Introducing Our Analysis and Visualization Software

MRes Mapper

Take Control

with Our Advanced Device Control and Data Acquisition Software (MRes Mapper)

MRes 2000 Software 200 mm

Empower yourself with precision and efficiency in semiconductor research and development using our state-of-the-art device control and data acquisition software. Designed to streamline your workflow and maximize your productivity, our software offers unparalleled features tailored to meet your unique needs:

Customizable 2D Mapping Plans

Craft individual 2D mapping plans tailored to your specific requirements, allowing you to scan across semiconductor wafers with precision and flexibility.

Recipe Definition for Seamless Workflow

Define recipes encompassing crucial sample information and 2D mapping plans effortlessly. Capture vital details such as wafer material (e.g. Silicon or GaAs) and the presence of thin conductive layers, ensuring accurate data acquisition for diverse applications.

Live Data Acquisition with Comprehensive Visualization

Experience real-time data acquisition with insightful visualization tools. Our software provides live data displays, including 2D maps, histograms, and statistical analysis, empowering you to monitor and analyze your data with unparalleled clarity.

Seamless Data Management with SQL Database Integration

Effortlessly manage your data with seamless integration with SQL databases. Store your valuable data securely and access it with ease, ensuring efficient data retrieval and analysis whenever you need it.

Flexible Export Options for Enhanced Accessibility

Choose from automatic or manual export options for your data reports. Generate ASCII result reports containing comprehensive data sets effortlessly. Plus, with just one click, download 2D plots of your data and automatically generated result reports in PDF format for instant accessibility.

Customizable Display of Physical Properties

Tailor your data visualization to your specific needs by choosing which physical properties to display. Whether you’re measuring semiconductor wafer properties or thin conductive films, our software puts you in control.

Individual Color Themes

Customize your visualization experience with personalized color themes, reducing eye strain and enhancing visibility to suit your preferences.

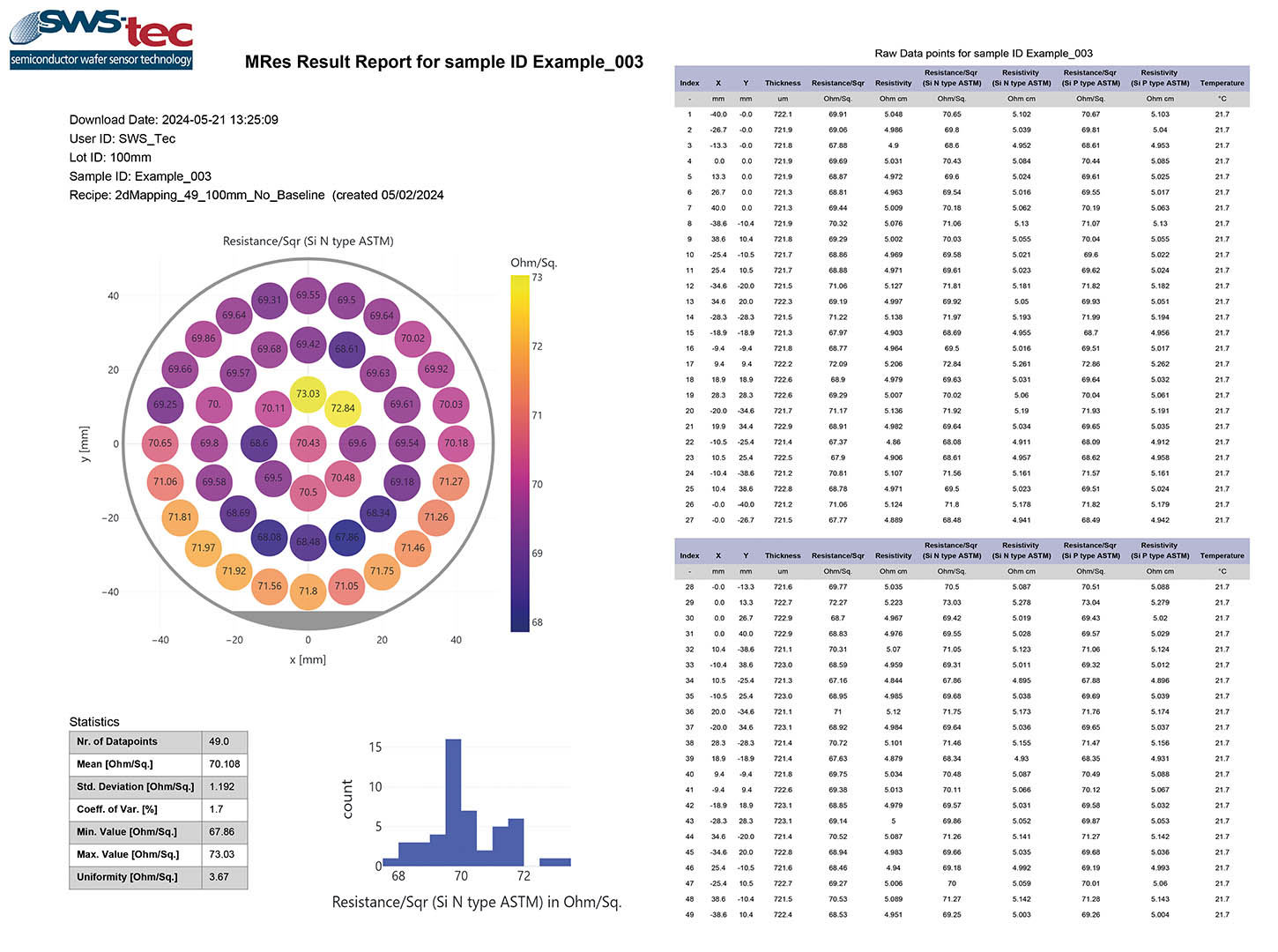

Visualizing Semiconductor Measurement Results

The MRes 2000 Control Software showcases measurement results from a 49-point mapping plan, demonstrated here for a Ø 100 mm Silicon wafer. The results are displayed in a color-coded data plot, a histogram for easy visualization of data-value distribution, and a statistics table.

Within the software, users can seamlessly switch between different physical quantities such as Thickness (bright image), Resistance (dark image), and Resistivity. Additionally, they have the option to toggle between raw and corrected values, adhering to the standards set by the American Society for Testing an d Materials (ASTM).

Furthermore, the user can choose between different themes, including bright and dark representation of the control software.

Data table

The MRes 2000 Control Software presenting the measurement results of a 49-point mapping plan, exemplified here for a Ø 100 mm Silicon wafer. Additionally to the graphical data representation, shown in the figure above, all physical quantities can also be shown within a data table.

Result report

MRes 2000 Control Software export functions: The export functions include automatically generated result reports in PDF format, ensuring comprehensive documentation of experimental outcomes, shown on the left side. Additionally, the software facilitates exporting data in ASCII format, which offers flexibility for further analysis. Excel format is also supported, enabling seamless integration with existing data management systems. Users can also download static images of color-coded data plots, providing a quick overview of experimental results.

Mapping plan

The MRes 2000 Control Software displays measurement results obtained from a custom-made mapping plan, shaped like an Ω. Custom recipes, including mapping plans, are stored within a database, enabling users to easily select the required mapping plan for their

current needs.

MRes DataViz Software

Introducing Our MRes Data Analysis and Visualization Software

MRes DataViz software

- 2d and 3d data analyzation

- 3d data point interpolation

- Direct comparison of different physical properties of the same wafer, for example Resistivity and Thickness

- Cross sectional analysis at arbitrary angles

- Data access via SQL Database

- One click export of a “Result Report pdf”, static and interactive figure

- Individual Color Theme to reduce eye strain, optimal visibility and personal preference

MRes 2000 Software 200 mm: Unlock the full potential of your high precision data with our innovative software tailored for the semiconductor industry. Beyond just measuring, our software empowers you to delve deep into your data, providing insights that drive breakthroughs in research and development.

Here’s what sets our software apart:

- 2D and 3D Data Analysis: Gain comprehensive insights into your data with advanced analysis capabilities that extend into both two and three dimensions.

- 3D Data Point Interpolation: Seamlessly fill in the gaps in your data with precision through our sophisticated interpolation algorithms, ensuring a complete and accurate picture.

- Direct Comparison of Different Physical Properties: Easily compare various physical properties of the same wafer, such as resistivity and thickness, enabling you to identify correlations and optimize performance.

- Simultaneous Comparison of Same Physical Properties Across up to Four Wafers: Effortlessly compare the same physical property, such as resistivity, across up to four different wafers simultaneously. Gain deeper insights into material consistency and performance variation with ease.

- Cross Sectional Analysis at Arbitrary Angles: Explore your specimens from any angle with our flexible cross sectional analysis tools, providing a deeper understanding of their internal structures.

- Data Access via SQL Database: Effortlessly manage and retrieve your data with the power of SQL database integration, ensuring efficient workflows and seamless access to information.

- One Click Export of Result Reports: Streamline your reporting process with our intuitive one click export feature, giving you the opportunity of generating both PDF reports and static or dynamic figures with ease.

- Individual Color Themes: Customize your visualization experience with personalized color themes, reducing eye strain and enhancing visibility to suit your preferences.

MRes 2000 Software 200 mm

At the forefront of innovation, our software is designed to empower semiconductor researchers and developers like you to unlock new insights, accelerate discoveries, and drive progress in the industry.

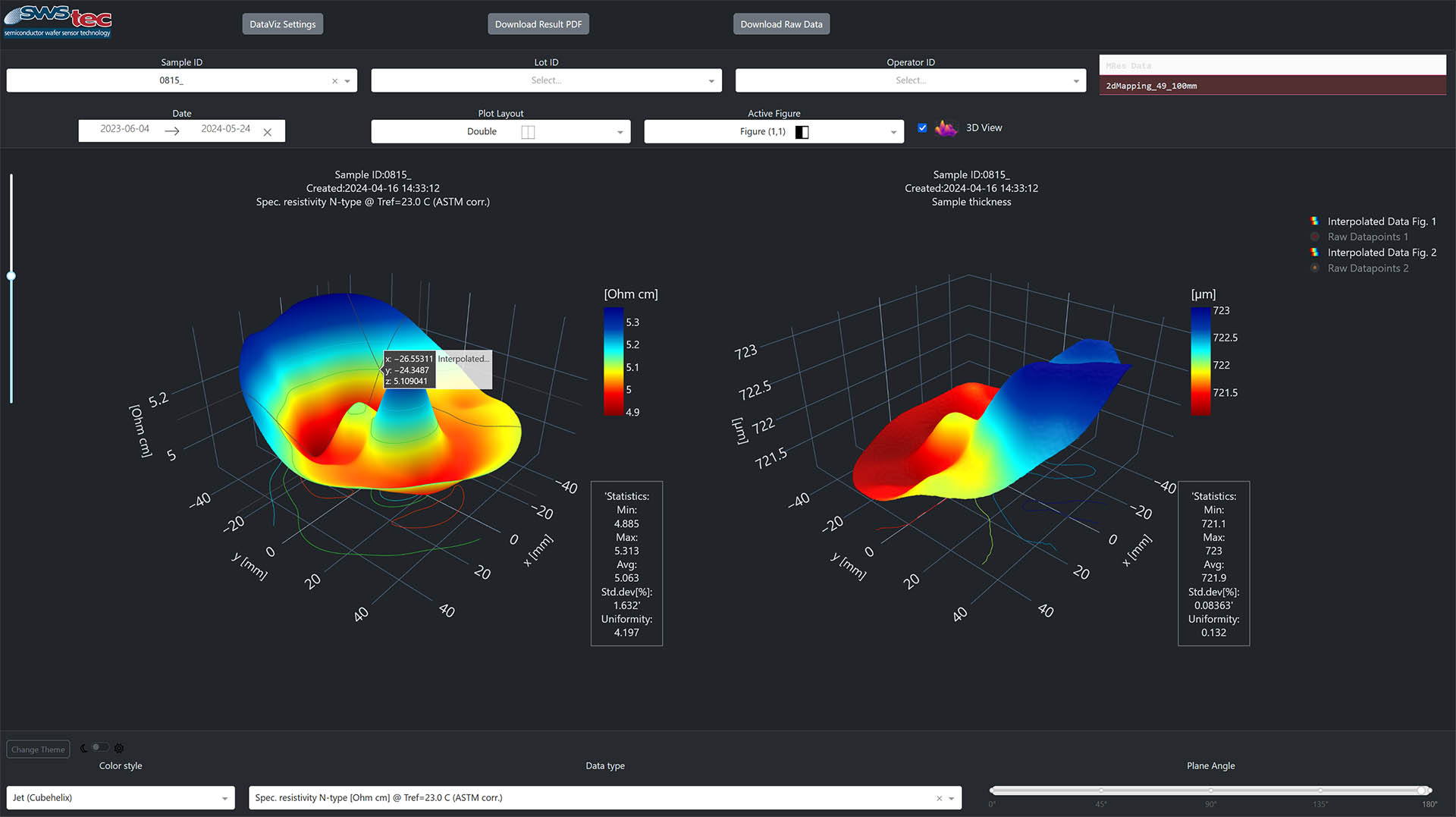

MRes DataViz (Spec. resistivity N-type + Sample thickness)

MRes Data Analysis and Visualization Software demonstrating a direct comparison of various physical quantities within the same specimen. Illustrated here using a Ø 100 mm Silicon wafer, the software offers synchronized 3-dimensional views across multiple graphs, facilitating the analysis of dependencies between parameters like Resistivity and Thickness. We leveraged 49 distinct measurement points across the wafer for both Thickness and Resistance, enabling the calculation of 3-dimensional interpolated data.

Additionally, users can select from different themes, including dark and bright modes.

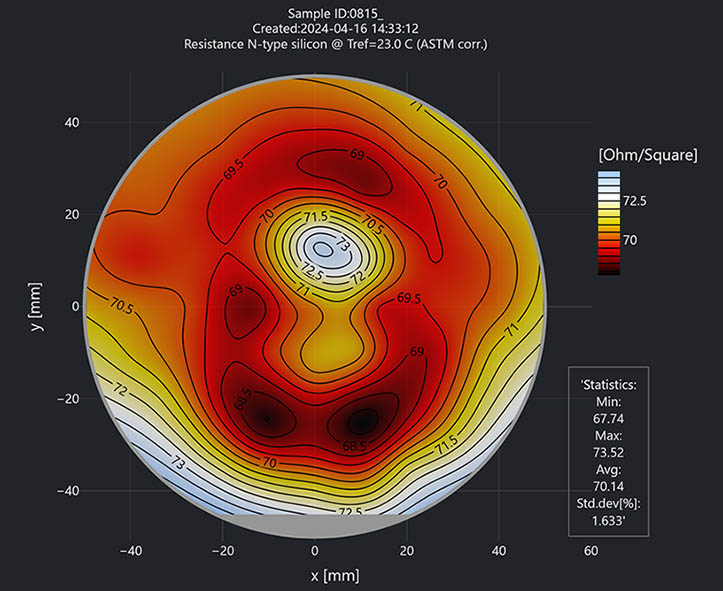

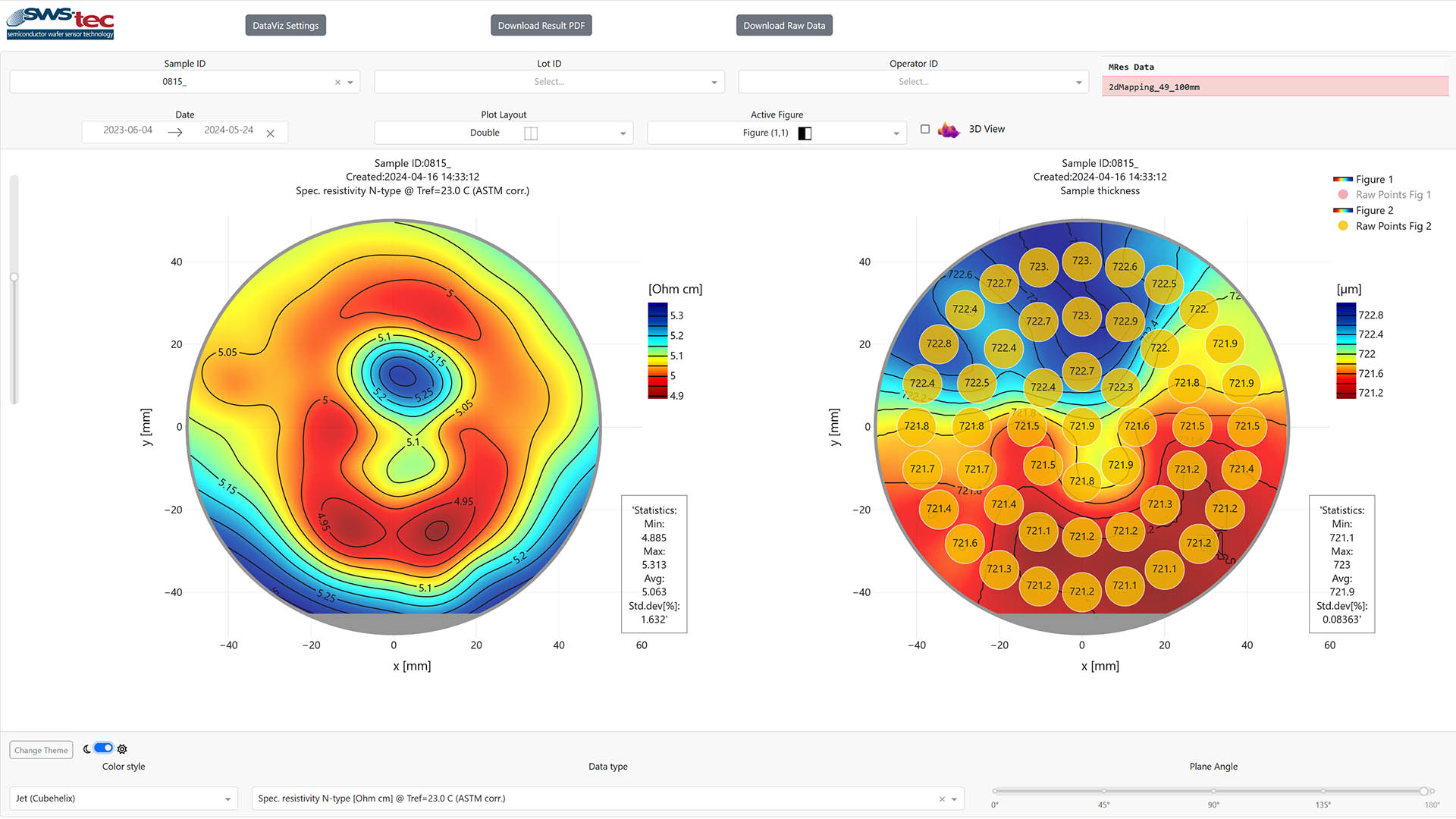

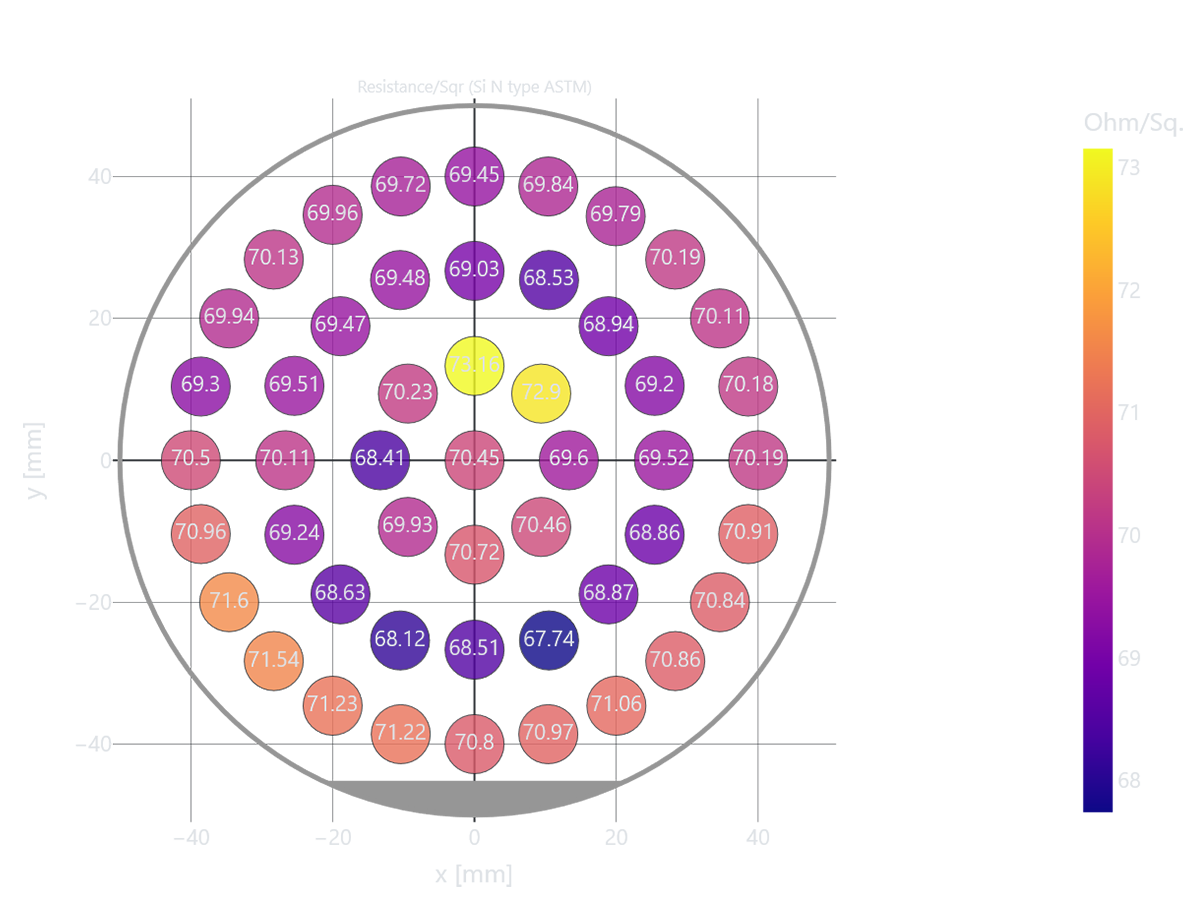

MRes DataViz 2d-Mapping

MRes Data Analysis and Visualization Software (bright mode) offers a 2-dimensional view of the same data as shown in the figure above. The 49 distinct measurement points across the wafer, used for calculating the interpolated data, are exemplarily displayed on the right side of the graph.

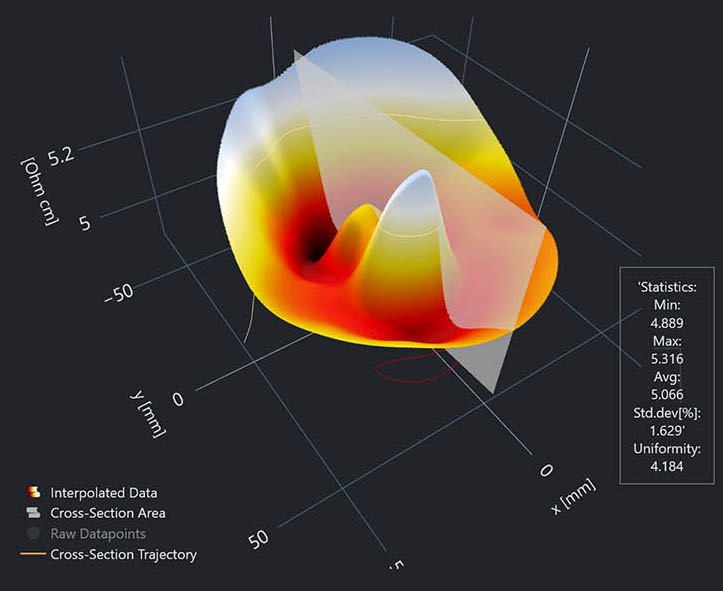

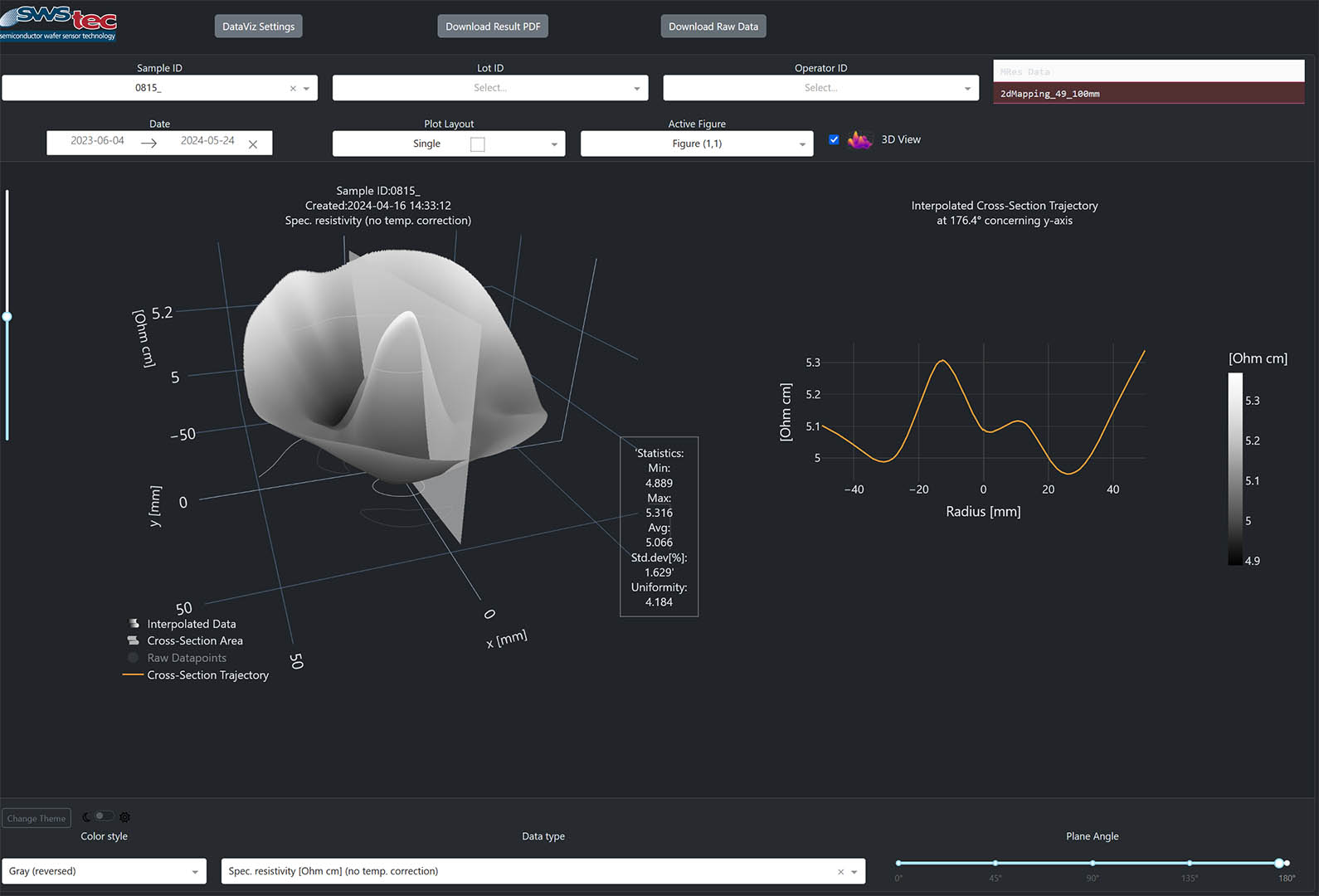

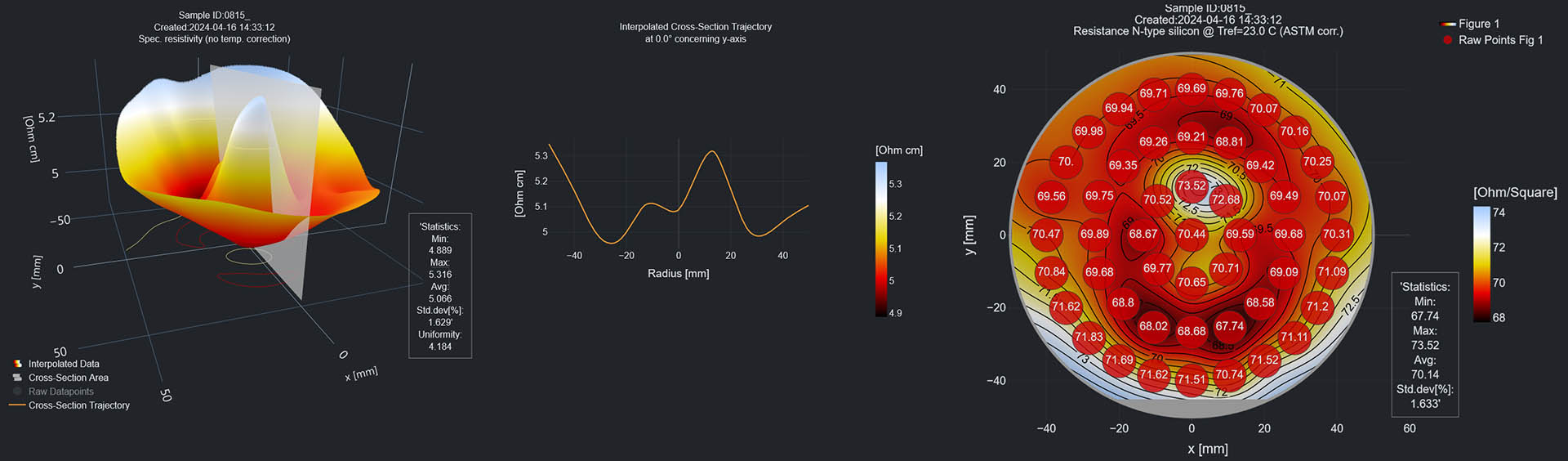

3-dimensional Cross Section Analysis

The MRes Data Analysis and Visualization Software demonstrates a 3-dimensional cross-section analysis. Users can analyze physical quantities, such as Thickness and Resistivity, using an interpolated cross-section area indicated by the grey shaded plane in the left image. The cross-sectional data is presented in a separate graph to the right of the 3-dimensional data, and users can rotate the cross-section by 360°. Leveraging 49 distinct measurement points distributed across the wafer ensures precise calculation of the interpolated data. The data showcased in this figure was acquired from a Ø 100 mm Silicon wafer.

MRes DataViz: One click image download.

One click image download from our MRes Data Analysis and Visualization Software for a 3-dimensional cross-section analysis and the corresponding 2-dimensional mapping points, shown in the left and right figure, respectively.

All physical quantities such as Thickness, Resistance and Resistivity can be analyzed with the assistance of an interpolated cross-section area, indicated by the grey shaded plane in the central image. The cross-sectional data is presented in a separate graph to the right of the 3-dimensional data, whereas the cross section can be rotated by 360°.

Utilizing 49 distinct measurement points distributed across the wafer, as shown in the right image, allows for precise calculation of the interpolated data. The data showcased in this figure was acquired from a Ø 100 mm Silicon wafer.

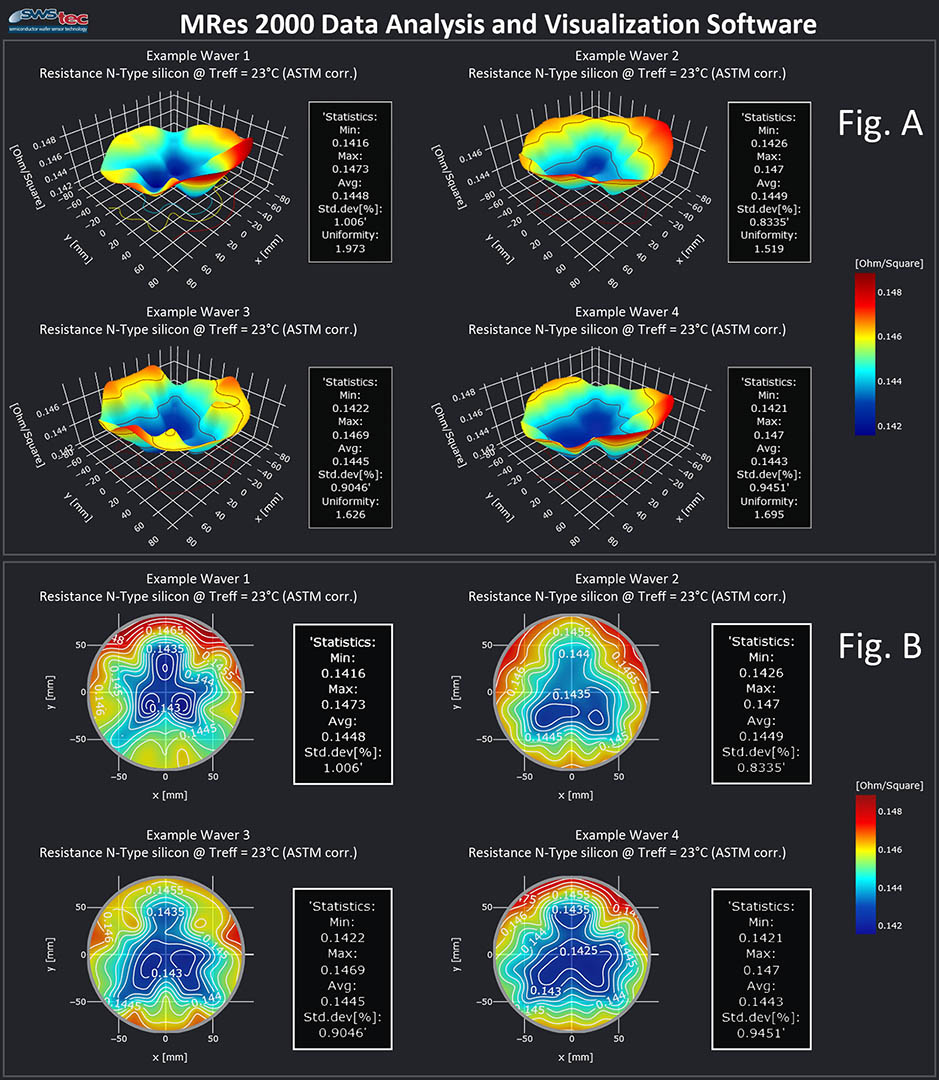

Our MRes Data Analysis and Visualization Software allows for a comparison of up to four different datasets. You can explore these datasets in both 3-dimensional (figure A) and 2-dimensional (figure B) presentations. Choose between analyzing the same physical quantity for different wafers (as presented in this figure), different physical quantities for the same wafer (not shown here), or a combination of both.

We leveraged 49 distinct measurement points across the wafer for Thickness and Resistance, enabling precise calculation of 3-dimensional interpolated data. The data showcased in these figures was acquired from four different Silicon wafers.

We are here to help!

Information you provide in the form is used and stored to process your enquiry and, if you have allowed the cookies, to improve content personalisation.

SWS-Tec processes personal information responsibly. For more information, please review our Privacy Policy (General Data Protection Regulation/GDPR).

* Mandatory field

Office

D-85643 Steinhoering, Germany

Hours

M-F: 9am – 5pm

S-S: Closed

![MRes 2000 [200 mm] Mapper - All physical quantities can also be shown within a data table](https://sws-tec.com/wp-content/uploads/2024/05/MRes-2000-200-mm-Mapper-All-physical-quantities-can-also-be-shown-within-a-data-table.jpg)

![MRes 2000 [200 mm] Mapper - Mapping Plan](https://sws-tec.com/wp-content/uploads/2024/05/MRes-2000-200-mm-Mapper-Mapping-Plan.jpg)